Carb Icing - Prevention is Always Better than Cure

- Garth Calitz

- May 31, 2023

- 3 min read

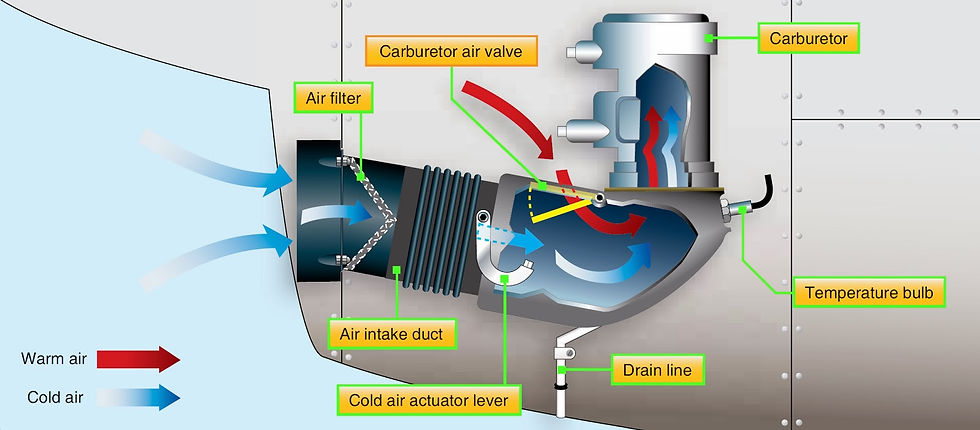

Fuel induction system icing, often referred to as “Carburettor Icing”, is the build-up of ice in the fuel induction system and can affect all types of piston engine aeroplanes, helicopters and gyroplanes. Our current weather conditions in the inland regions of South Africa are the perfect recipe for Carb Icing with falling temperatures and high relative humidity.

There are three basic types of fuel induction system icing that may affect piston engines:

Impact Ice.

This is formed by the impact of moist air at temperatures between -10°C and 0°C on air scoops, throttle plates, heat valves, etc. It usually forms when visible moisture such as rain, snow, sleet, or clouds are present. Most rapid accumulation can be anticipated at -4°C. This type of icing can affect fuel injection systems as well as carburettor systems and is also the main type of icing hazard for turbocharged engines.

Fuel Ice.

This forms at, and downstream from, the point that fuel is introduced into the carburettor when the moisture content of the air freezes as a result of the cooling caused by fuel vaporisation. It generally occurs between +4°C to +27°C but may occur at even higher temperatures. It can occur whenever the relative humidity is more than 50%.

Throttle Ice.

This is the most common, earliest to show and most serious carburettor icing. It is formed at or near a partly closed throttle valve (sometimes called the “butterfly valve”). The water vapour in the induction air condenses and freezes due to the venturi effect cooling the air as it passes the throttle valve. Since the temperature drop is usually around 3°C, the optimum temperature for forming throttle ice is between 0°C to +3°C although a combination of fuel and throttle ice could occur at much higher ambient temperatures.

The first indication of carburettor icing in an aircraft with a fixed-pitch propeller is a decrease in engine rpm, which may be followed by engine roughness. In an aircraft with a constant-speed propeller, carburettor icing is usually indicated by a decrease in manifold pressure, but no reduction in rpm, propeller pitch is automatically adjusted to compensate for loss of power. Thus, a constant rpm is maintained. Although carburettor ice can occur during any phase of flight, it is particularly dangerous when using reduced power during a descent. Under certain conditions, carburettor icing could build unnoticed until power is added.

If Icing is left untreated it will lead to engine running very rough, increased vibration, further loss of performance and eventually the engine will just quit due to fuel starvation.

Prevention is always better than the Cure.

In the event that carburettor icing is encountered, full carburettor heat should be applied immediately. Engine performance may initially get worse, but the ice will begin to clear after about 30 seconds and power will return to normal.

For extended periods of flight with reduced power settings, the power should be routinely increased and FULL carburettor heat applied for around 15 seconds to ensure that the engine stays sufficiently warm to melt any ice.

If flying in conditions that appear conducive to the development of carburettor ice, carburettor heat should be applied at regular intervals as both a preventative measure against the formation of ice and a method to test whether or not carburettor ice is developing. If a normal drop in RPM or manifold pressure accompanies the application of carburettor heat, it is reasonably certain that ice is not forming in the carburettor. The use of carburettor heat will decrease engine performance by up to 15% so pilots should beware of flying around with it continuously selected; the aircraft will use more fuel than planned for and this practice could potentially decrease the life of the engine due to an inappropriate mixture setting.

All aircraft types/fuel combinations can have slightly different characteristics associated with carburettor icing; an aircraft operating on AVGAS will have different characteristics to the same type operating on MOGAS. Pilots should know and understand what happens to their particular aircraft/fuel combination in various flight conditions.

Remember that, as a rule-of-thumb: Power OFF = Carb Heat ON

Please be safe out there

Comments